Linear bearings are essential components in various mechanical systems, providing smooth and precise linear motion. Accuracy is a crucial factor when considering the performance of linear bearings, especially in applications where precision is critical. In this article, we will explore the accuracy of linear bearings, factors influencing their accuracy, and methods used to improve precision.

- Types of Linear Bearings: There are several types of linear bearings, each offering different levels of accuracy:

- Plain Bearings: Plain bearings, also known as bushings, are simple bearing surfaces that provide low-friction linear motion. While they offer cost-effective solutions, plain bearings tend to have lower accuracy compared to other types.

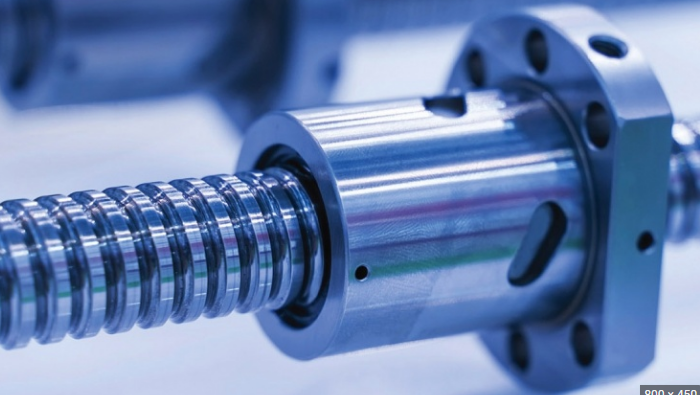

- Ball Bearings: Ball bearings consist of rolling elements (balls) housed in a cage, providing smooth and precise linear motion. They offer relatively high accuracy and are commonly used in applications where precision is essential.

- Roller Bearings: Roller bearings use cylindrical or tapered rollers to facilitate linear motion. They are known for their high load-carrying capacity and are commonly used in heavy-duty applications. Roller bearings generally provide good accuracy but may not match the precision of ball bearings.

- Needle Bearings: Needle bearings use cylindrical rollers with a small diameter, offering high load capacity and good accuracy. They are commonly used in applications where compact size and high precision are required, such as in medical devices and robotics.

- Factors Affecting Accuracy: Several factors can influence the accuracy of linear bearings:

- Manufacturing Tolerances: The precision with which the bearings are manufactured affects their accuracy. shengbenzhejiangchina.Smaller tolerances result in higher accuracy, but tighter tolerances may increase manufacturing costs.

- Load and Force Distribution: The applied load and the way forces are distributed across the bearings can affect their accuracy. Uneven loading or excessive forces can cause deflection and reduce accuracy.

- Mounting and Alignment: Proper mounting and alignment of linear bearings are crucial for achieving optimal accuracy. Misalignment or improper installation can lead to increased friction, vibration, and reduced precision.

- Lubrication: Adequate lubrication is essential for minimizing friction and ensuring smooth motion. Insufficient or improper lubrication can cause increased friction, leading to decreased accuracy over time.

- Improving Accuracy: Several methods can be employed to improve the accuracy of linear bearings:

- Preloading: Preloading refers to applying a controlled axial load on the bearing to reduce clearance and minimize play. This technique can increase the stiffness and accuracy of the bearing system.

- Linear Guides: Linear guides provide additional support and guidance to the linear bearings, enhancing their accuracy. They often incorporate recirculating ball or roller elements, offering improved rigidity and precision.

- High-precision Manufacturing: Advanced manufacturing techniques and tighter tolerances can enhance the accuracy of linear bearings. Precision grinding, honing, and specialized surface treatments can improve the smoothness and accuracy of bearing surfaces.

- Maintenance and Inspection: Regular maintenance and inspection help identify and rectify any issues that may affect the accuracy of linear bearings. Proper lubrication, cleaning, and adjustment can ensure optimal performance.

Conclusion: Accuracy is a crucial aspect when evaluating the performance of linear bearings. The type of bearing, manufacturing tolerances, load distribution, mounting, and lubrication all contribute to the accuracy of the linear motion system. By considering these factors and employing appropriate measures such as preloading, the use of linear guides, high-precision manufacturing, and regular maintenance, the accuracy of linear bearings can be enhanced. It is essential to choose the appropriate type of linear bearing and implement measures to optimize accuracy in applications where precision is critical.